Elliptical machines are popular in gyms, apartments, hotels, and home fitness spaces because they provide a low-impact, full-body workout. But like any piece of fitness equipment with moving parts and electronics, ellipticals experience wear over time. When small issues are ignored, they can quickly turn into costly repairs, extended downtime, or safety concerns.

This elliptical repair troubleshooting guide explains the most common machine problems, outlines safe DIY steps you can take, and clarifies when professional service is the smarter and more cost-effective option.

Understanding How Elliptical Machines Wear Over Time

Ellipticals rely on a combination of moving joints, belts, bearings, resistance systems, and electronic components working together smoothly. Daily use, sweat exposure, dust buildup, and uneven flooring all contribute to gradual wear.

Early warning signs often appear as noise, resistance inconsistencies, or instability. Addressing these symptoms early can significantly extend equipment life and help avoid unexpected repair expenses.

👉 Catching problems early is one of the simplest ways to reduce long-term repair costs and equipment downtime.

Common Elliptical Machine Problems and What They Mean

Squeaking, Creaking, or Grinding Noises

Unusual sounds are among the most frequent elliptical complaints and typically indicate friction or looseness in moving components.

Common causes include:

Dry or worn pivot points

Loose bolts or fasteners

Dirty rails or rollers

Aging bearings

DIY troubleshooting tips:

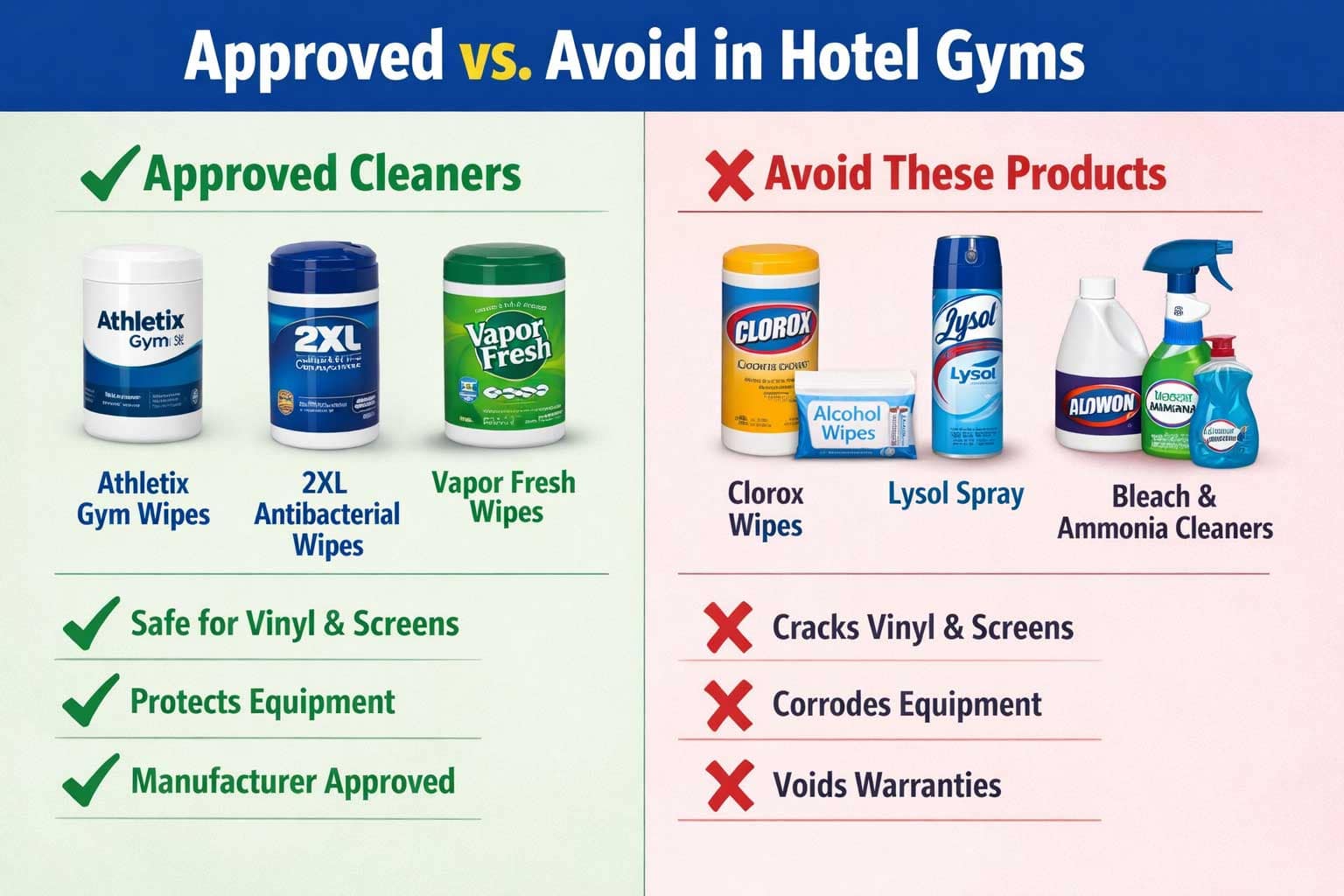

Clean rails and rollers using a non-abrasive cloth and a mild solution of 2% Dawn dish soap and water

Tighten accessible hardware according to manufacturer torque guidelines

Apply a manufacturer-approved lubricant to moving joints (never WD-40)

If grinding continues after cleaning and lubrication, internal components may already be worn and should be inspected by a qualified technician.

Uneven or Inconsistent Resistance

Resistance issues disrupt workouts and often signal deeper mechanical or electrical problems.

Common causes include:

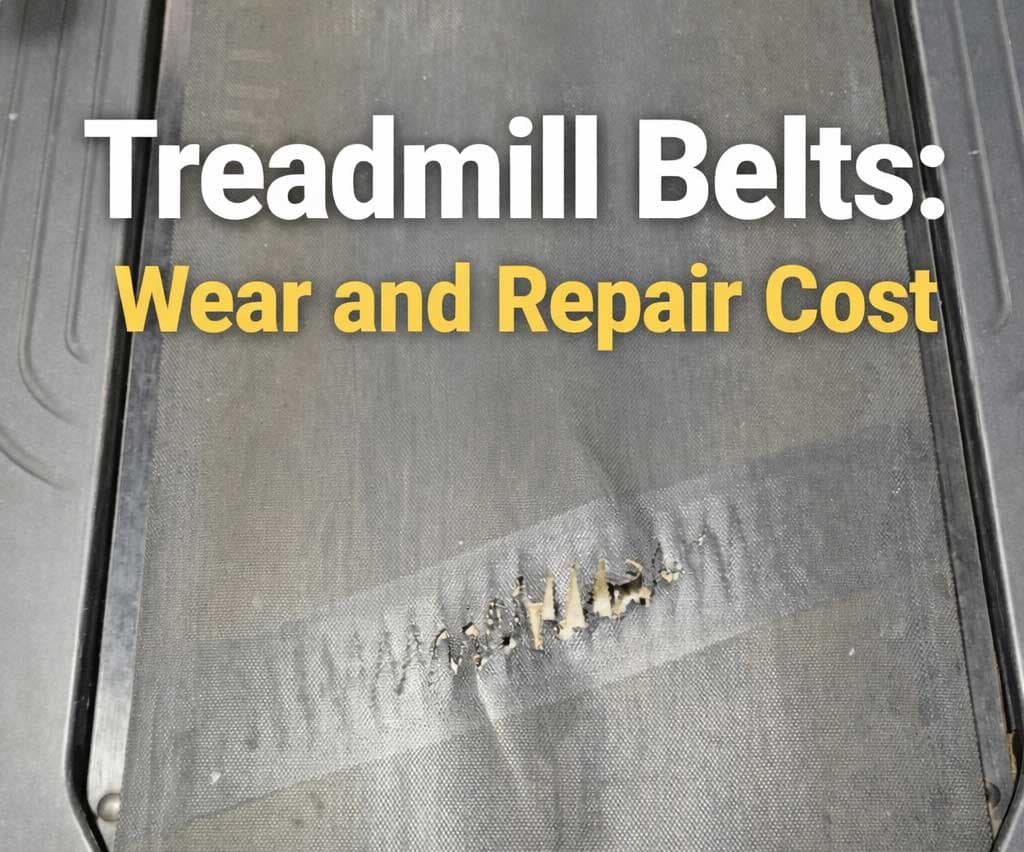

Worn or slipping drive belts

Misaligned magnetic resistance systems

Failing resistance motors

Power supply inconsistencies

DIY troubleshooting tips:

Restart the machine and recalibrate, if the model allows

Inspect visible belts for fraying or slack

Confirm the unit is plugged into a dedicated power outlet

When resistance fluctuates randomly or stops responding to controls, professional diagnosis is typically required to prevent further damage.

Stability and Movement Issues That Affect Safety

Pedals Slipping or Feeling Unstable

Pedal instability is more than inconvenient—it presents a real safety risk.

Possible causes include:

Loose pedal arms

Worn bushings

Frame bolts loosening over time

DIY troubleshooting tips:

Check and tighten pedal arm hardware

Inspect for visible cracks or excessive play

Verify the machine is level on the floor

If instability remains after tightening, continued use may increase injury risk and should be addressed professionally.

Elliptical Wobble or Rocking Motion

Wobbling is often related to installation or flooring rather than internal components.

Troubleshooting steps:

Adjust leveling feet until all contact points are stable

Place the machine on a solid, flat surface

Avoid thick rubber flooring that compresses unevenly

Persistent wobble on a flat surface may indicate frame fatigue or structural issues requiring expert evaluation.

Console and Display Problems

Blank Screens or Unresponsive Controls

Electronic failures are usually obvious to users and should not be ignored.

Typical causes include:

Loose wiring connections

Static discharge damage

Sweat-related moisture intrusion

Aging circuit boards

DIY troubleshooting tips:

Power cycle the unit and check accessible connections

Replace batteries if the console is battery-powered

Clean around buttons and displays using a dry cloth

If the console flickers, resets mid-workout, or fails completely, untrained troubleshooting can increase repair costs.

Preventive Maintenance Tips to Reduce Breakdowns

Routine maintenance significantly reduces unexpected elliptical repair needs.

Best practices include:

Wiping down rails and pedals daily

Inspecting bolts and joints monthly

Keeping the surrounding area dust-free

Scheduling annual professional inspections

👉 Preventive maintenance not only improves performance but also helps identify wear before it becomes a costly failure.

When DIY Fixes Are No Longer Enough

While basic upkeep resolves minor issues, some symptoms clearly indicate professional service is needed.

Signs It’s Time to Call a Technician

Loud grinding or metal-on-metal noise

Resistance failure during workouts

Electrical smells or repeated power loss

Structural instability or cracked components

Attempting advanced repairs without proper tools or training can worsen damage and increase long-term costs.

Why Professional Elliptical Repair Protects Your Investment

Certified fitness equipment technicians are trained to diagnose underlying issues such as bearing wear, resistance motor failure, and frame stress that are not visible externally. Professional repairs help ensure equipment meets safety standards, reduce liability risks in shared spaces, and extend usable lifespan.

This is especially important in commercial environments where equipment reliability directly affects user satisfaction and operational continuity.

Final Thoughts on Keeping Ellipticals Running Smoothly

Elliptical machines are dependable when properly maintained, but no equipment lasts indefinitely without care. Understanding common problems, performing safe maintenance, and knowing when to seek professional elliptical repair can prevent downtime and unexpected expenses.

Addressing issues early keeps workouts safe, users satisfied, and equipment performing as intended—making proactive care a smart long-term strategy for any fitness environment.

Need professional elliptical repair or preventive maintenance?

Contact ServiceRX to keep your equipment safe, reliable, and ready for use.

Frequently Asked Questions About Elliptical Repair

What are the most common elliptical machine problems?

The most common elliptical problems include squeaking or grinding noises, uneven or inconsistent resistance, pedal wobble, rocking motion, and console or display failures. These issues are typically caused by normal wear on moving parts, loose hardware, lack of lubrication, electrical faults, or environmental factors like uneven flooring.

Why is my elliptical making squeaking or grinding noises?

Squeaking usually results from dry pivot points, dirty rails, or loose fasteners, while grinding often indicates worn bearings or internal components. Light cleaning and proper lubrication may help, but persistent grinding noises usually require professional inspection to prevent further damage.

What causes uneven resistance on an elliptical machine?

Uneven resistance is commonly caused by worn drive belts, misaligned magnetic resistance systems, failing resistance motors, or power supply inconsistencies. While recalibration or resets may temporarily help, ongoing resistance issues typically require professional repair.

Is it safe to keep using an elliptical that feels unstable?

No. An elliptical that wobbles, rocks, or has slipping pedals can increase the risk of injury. Instability may be caused by loose pedal arms, worn bushings, uneven flooring, or structural fatigue. Continued use without repair is not recommended.

Why does my elliptical wobble even after leveling it?

If wobbling continues after adjusting leveling feet and placing the machine on a solid surface, the issue may be related to frame fatigue, worn stabilizers, or internal structural wear. These conditions should be evaluated by a trained technician.

Why is my elliptical console not turning on or responding?

Console issues are often caused by loose wiring, depleted batteries, moisture exposure from sweat, static discharge, or aging circuit boards. Basic power checks may help, but recurring display problems usually require specialized diagnostics.

How often should elliptical machines be serviced?

Light cleaning should be performed daily, and hardware inspections are recommended monthly. In commercial environments such as gyms, apartments, and hotels, professional preventive maintenance is typically recommended at least once per year to reduce downtime and extend equipment life.

When should I call a professional for elliptical repair?

You should contact a professional if you experience grinding noises, resistance failure, repeated console errors, electrical smells, power loss, or structural instability. These symptoms often indicate internal issues that cannot be safely resolved with DIY fixes.

Can regular maintenance really extend the life of an elliptical?

Yes. Routine maintenance reduces friction, prevents premature component failure, and helps identify wear early. Well-maintained ellipticals generally last significantly longer and perform more consistently than neglected machines.

Are elliptical repair needs different in commercial gyms?

Yes. Commercial ellipticals experience higher daily usage, which accelerates wear on belts, bearings, pedals, and electronics. Professional servicing is especially important in commercial settings to maintain safety, reliability, and member satisfaction.

Is professional elliptical repair worth the cost?

In most cases, yes. Early professional repair often prevents more expensive part replacements, reduces downtime, and lowers liability risks—making it a cost-effective long-term solution for both residential and commercial fitness environments.